Project of the month July 2018:Combined punching and milling unit for inline prefabrication

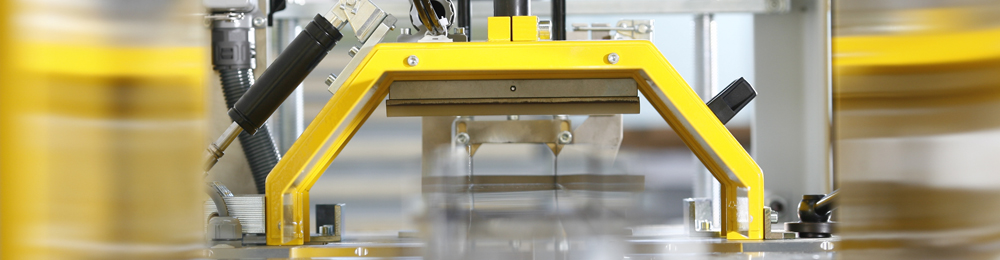

Punching and milling unit based on ME 41/6.1

The task:

- Introduction of position-specific punching and lateral sectioning of profiles.

- Integration of the unit in an existing extrusion line.

- Objective: To avoid prefabrication work outside of the extrusion line.

The solution:

- Punching and milling unit based on ME 41 / 6.1 with 2 fixed milling units. The punching unit stamps the desired punch pattern, respecting the distance to the profile edge. The milling units process the profile laterally. The punching / milling pattern is programmed via the machine controller ME Control 20/2.

1. Punching unit ME 41/6.1

|

|

| Punching unit ME41/6.1 | Punching tool |

- Punching carriage travel: 25 mm

- Work principle: pneumatic

- Punching force: 3000 N

- Punching stroke: 10mm

- Punching sequence: up to 100 cycles/min

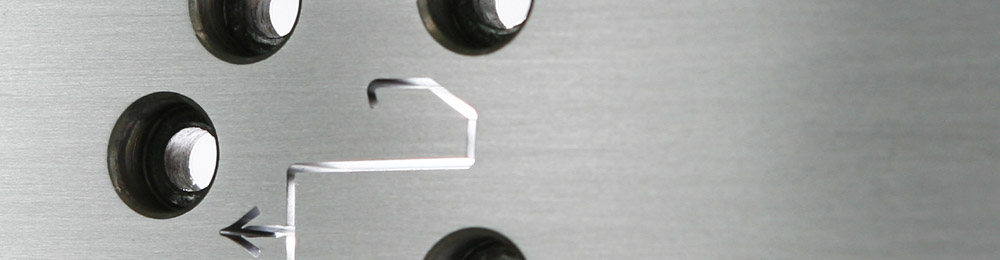

2. Milling unit

|

|

| Milling unit | Manually adjustable milling stops |

|

|

| Milling cutters with suppression element | Controller ME Control 20/2 |

- Lateral, pneumatic service of the milling cutters

- Manually adjustable stops for milling depth, incl. display

- Milling tool holders Ø 10 mm

- Milling cutters can be switched off individually

- Programmable milling length and distance between 2 millings