We proudly present our Project of the month:

Project of the month January 2020

IDE machines – used as well as new

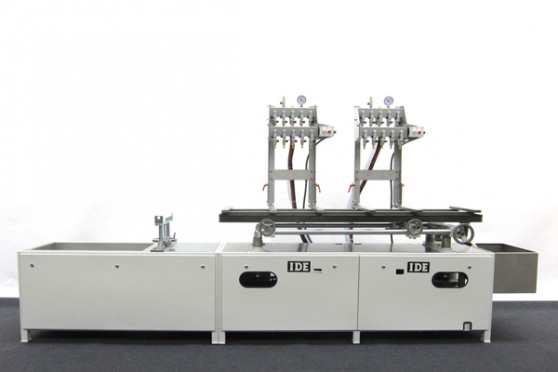

Below is another generally overhauled downstream equipment of IDE.

Of course all machines will be throughly quality-checked and assessed. The condition and all functions of the machines are checked in detail and,if necessary, professionally repaired or prepared to achieve the highest quality standards.

If we have aroused your interest in one of our available used and new machines, please feel free to contact our IDE contact persons. Here you can find out which machines are ready for delivery or which are currently being refurbished.

|

|

| Calibration unit before disassembly | Calibration unit overhauled |

|

|

| Haul-off unit before disassembly | Haul-off unit overhauled |

|

|

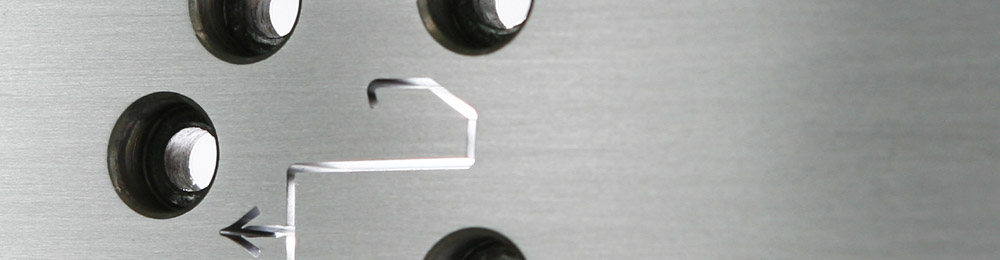

| Detail Haul-off unit before disassembly | Detail Hau-off unit overhauled |

|

|

| Detail Saw unit before disassembly | Detail Saw unit overhauled |

|

|

| Overhauled downstream equipment | Overhauled downstream equipment |

|

|

| Overhauled downstream equipment |

Project Archive

Project of the month December 2019

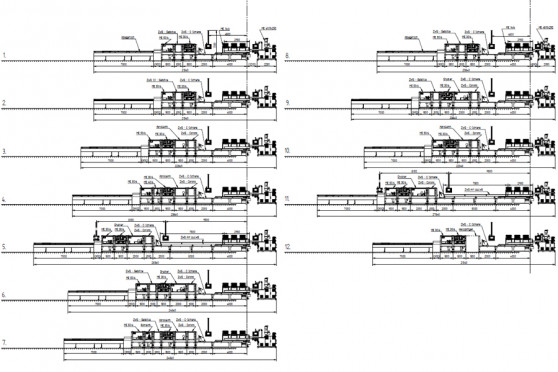

*CoExtrusion line:*

Single screw extruder ME 45/5x25D Single screw

extruder MEB 30/5x25D Calibration unit ME 14/6. 1 Haul-off

unit ME 30/6.

Project of the month October 2019:

drilling unit

*The task:*

Realisation of a longitudinal groove in the extrusion

direction at over 20 cycles per minute Variable option for

inserting the longitudinal groove in the controller Control

of an external saw unit Preparation of a chip extraction

device

*The solution:*

Dual drilling unit with two individually adjustable drill

drives Milling distance of 75 – 400 mm possible Additional

motorised axis for longitudinal grooves up to 30 mm in

length Wooden profile guide for easy machining

2 Zweifach Bohreinheit 3 Arbeitsbereich

Dual drilling unit

Drilling unit work area

4 Bohrkopf 5 Querverstellung

Drill head

Transverse shift

6 Abblassystem

Blow-off system

.

Project of the Month July 2019:

Mobile Production

The task:

5 existing lines with 60 different profiles made from a

wide range of thermoplastics – TPE, PVC-U, PS,PP, PMMA,

LD-PE, ASA and ABS – transferred to 2 new complete

extrusion lines. A variety of post-processing work, such as

pad printing, drilling, punching and the application of

adhesive tape, is to be carried out on both new lines.

Project of the month June 2019:

Refurbished calibration table ME 14/2

*The task:*

The ME 14/2 built in 1984 is to be repaired again. Check to

determine which functional parts can still be used Only

original parts are used when replacing functional parts.

Project of the month May 2019:

Punch-saw combination for twin-strand extrusion

The task:

Combined unit for punching and cutting twin-strand

profiles. Existing punching tools may be installed safely

and quickly.

Project of the month April 2019:

Tape applicator unit for various plastic profiles

The task:

A unit to apply specific adhesive tapes at the top and

bottom of various plastic profiles

The solution:

Machine unit width1,5m Inclusion of customer-specific

tape rolls Capacitive sensor for tape detection Tape access

control with torque-controlled drive Simple shifting of the

individual feeding systems

2019 04 01 Abrolleinheit Profile Komplette Zugaenglichkeit

2019 04 01 Abrolleinheit Profile Zufuehrsysteme

Abziehklebebaender

Complete frontal accessibility Feeding system for

adhesive tape rolls

2019 04 01 Abrolleinheit Profile Zufuehrsystem Doppel

Beklebung 2019 04 01 Abrolleinheit Profile

Zufuehrsystem Beklebung unten

Feeding system for taping up and down Sensor for taping

profile lower side

2019 04 01 Abrolleinheit Profile Sensor Banderkennung

Sensor for tape detection

.

Project of the month March 2019:

Dual carriage cut-off saw unit for defined fixed lengths

The task:

To cut rods to length with a finished piece tolerance of ±

0,05 mm

The solution:

Dual carriage cut-off saw ME 50/6. 2-D with 2 saw carriages

Saw carriage travel distance 400mm, motorized (cycle time 30

cuts/minute) Distance between saw carriages adjustable from

150 – 800mm, incl.

Project of the month February 2019:

Complete line for the production of prefabricated roller shutters

The task:

Complete line for two die systems Inline prefabrication

Data transmission with industrial hand-held scanner

The solution:

Extrusion line consisting of the following components:

ME 75/5x25D with mini ME Control/4 Die system consisting of

extrusion die and dry calibration, designed for a production

speed of 8m/min Calibration unit ME 14/6. 1 with 2

frequency-controlled vacuum pumps Haul-off unit ME 30/6.

Project of the month December 2018:

Complete line for the production of various filter profiles

The task:

Downstream line for more than 6 different filter profiles

with diameters of 15 – 120 mm Constructed mainly of

rustproof materials Spray waterbath with individual spray

bar adjustment Profile drying via suction technology Belt

haul-off with constant center of extrusion Cutting unit

for profiles up to 125mm in diameter

The solution:

Extrusion downstream line consisting of the following

components:

Calibration downstream with more than 60 spray nozzles

Exchangeable spray ring at the inlet side Suction ring with

exchangeable nozzles of different dimensions at the

outlet-side Belt haul-off with centralized manual gap

adjustment Rotary cutting unit for profile diameters up to

125 mm

Einlaufseitiger Spruehring Spruehwasserbad

Spray ring at the inlet side Spray waterbath

Auslaufseitige Absaugtechnologie Bandabzug mit

Spaltverstellung

Suction technology at the outlet side Belt haul-off with

gap adjustment

Rotationsschneideinheit mit Schneidmatrize Steuerung

ME Control 20 4 Folgeeinheit

Rotation cutting unit Controller ME

Control 20/4.