Project of the Month July 2019:Mobile Production

The task:

- 5 existing lines with 60 different profiles made from a wide range of thermoplastics – TPE, PVC-U, PS,PP, PMMA, LD-PE, ASA and ABS – transferred to 2 new complete extrusion lines.

- A variety of post-processing work, such as pad printing, drilling, punching and the application of adhesive tape, is to be carried out on both new lines.

- It should be possible to change the units quickly and easily between both lines.

- Networking of all units for logging the desired process parameters

- Preselectable start-up parameters and production parameters

- 2 extruder panels for operation on the extruder and at the end of the line

The solution:

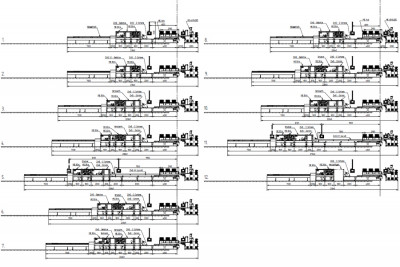

- 2 extrusion lines – 1x ME 45/5x25D and 1x ME60/5x25D

- 2 control panels per line for complete flexibility during operation/production.

- 15 downstream units that can be joined as required to form a new line.

- Complete data communication, plug-in supply lines.

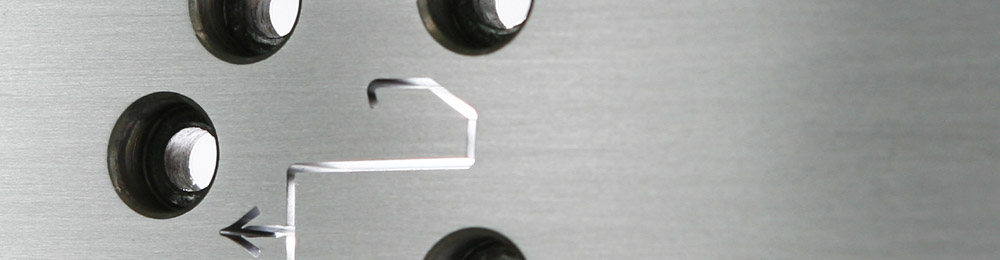

- Alignment in the customer's floor rail using locking bolts

| |

|

| Extruder ME 60/5x25D | Extruder control |

| |

|

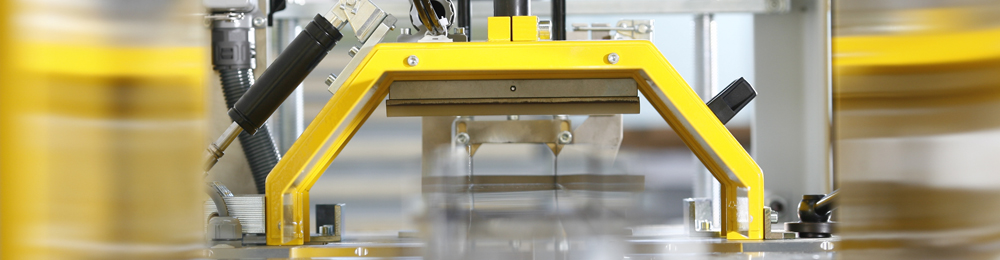

| Calibration table ME 14/6.3 | Fixing elements between the units |

| |

|

| Alignment - floor rail | Plug-in supply lines |

| |

|

| Drill unit | Pad printing |