Project of the month April 2018:Single extrusion machines in customized design for the production of technical profiles

Overall view ME 90/5x25D

The task:

Single screw extruder with melt pump, calibration unit in customer-specific design, haul-off unit for U-profiles up to w x h 500 x 250 mm

The solution:

1. Single scre extruder ME 90/5x25D

|

|

| Controller ME Control/3 | Cylinder heating zone, insulated ceramic heating elements |

- Asynchronous motor 53 kW

- Speed up to 49 rpm

- One-piece bimetallic cylinder

- Controller ME Control/3 for the operation and monitoring of the main extruder, the melt pump, a coextruder, the calibration unit ME 14/6.1 and the haul-off ME 3-205/1.

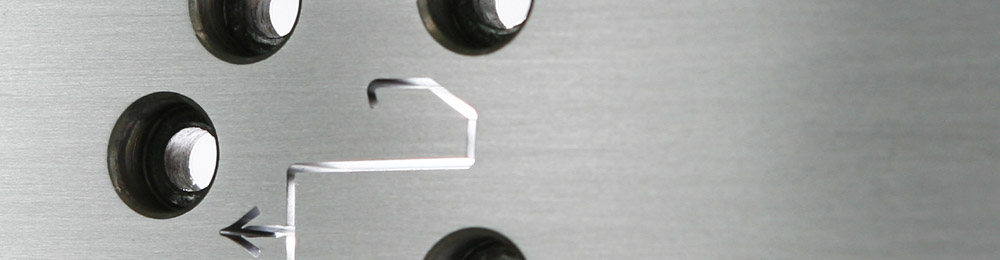

2. Calibration unit ME 14/6.1

|

|

|

Vacuum and water manifolds |

- Calibration table 400x1950 mm

- Table height adjustment 910 – 1060 mm, mechanical

- Two vacuum pumps, frequency-controlled (2x4,3 kW)

- Motorized longitudinal adjustment of the table, 300 mm

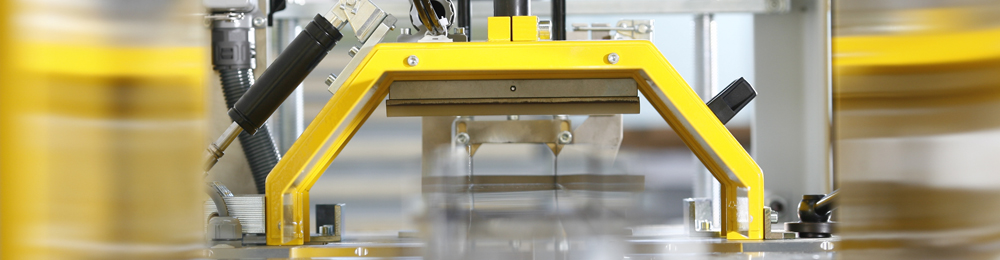

3. Haul-off unit ME 3-205/1-1500

|

|

| Elevated transport chains | Caterpillar clamping hydraulic |

- Haul-off speed 0,5 to 10,0 m/min

- Pulling force max. 15000N

- Drive 2 AC-Motors, à 3,8 kW

- Contact length 1500mm

- Caterpillar clamping: hydraulic

- Elevated transport chains