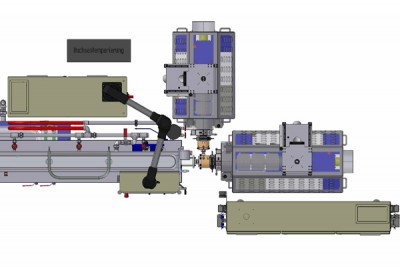

Project of the month June 2018:Complete coextrusion line for the production of medical tubes

Overview ME 30/5x25D + ME20x25D in coextrusion version with downstream

The task:

Extrusion line for use in a clean room consisting of three single-screw extruders, one calibration unit, online measuring and testing equipment and a haul-off / cutting unit for the production of over one hundred different mono- and coextruded tubes made from 26 different thermoplastic materials.

The solution:

1.) Three mobile single screw extruders, Ø45, Ø30 and Ø20mm, the entire electrical system of which is centrally located in two fixed control cabinets. These cabinets also accommodate the electrical system of the entire downstream line composed of a cooling section, online measuring and testing technology and a haul-off with a built-on rotary cutter.

|

|

| Controller ME Control /3 | Screws for different materials |

|

|

| Online measuring and testing technology | Complete line in a clean room |

- Control cabinet 1 with converters for 3 extruders including support air system

- Control cabinet 2 with line electrical system and line controller ME Control /3

- 2nd operator terminal near the haul-off with display of measurement results

- Extruder 45x25D, 15kW, 55rpm

- Extruder 30x25D, 4,0kW, 69rpm

- Extruder 20x25D, 2,2KW, 69rpm

- Mobile version, with plug-in connection to control cabinet

- Complete line with stainless steel panelling

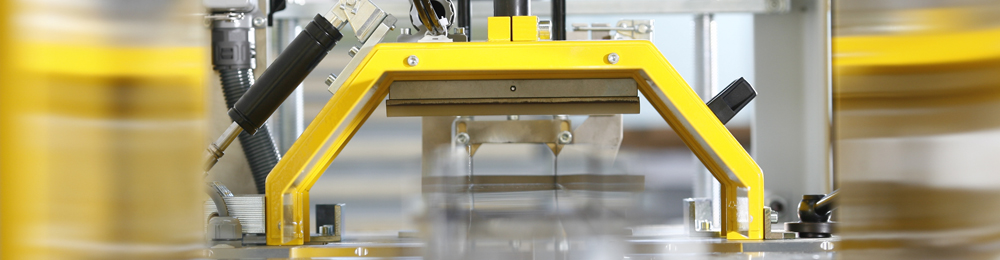

2.) Haul off ME 30/ 6.1

|

|

| Belt haul-off in stainless steel |

Second operator terminal for line operation and measurement display |

- 350mm contact length

- Haul-off speed up to 140 m/min

- Complete cladding in stainless steel

- Rotary cutter ME50/6.R1 mounted on the end face of the haul-off

- Various cutting bushes for different tubing sizes

3.) Cooling section and measuring / testing technology

|

|

| Ultrasonic measuring chamber/ Profile drying and measuring equipment | Waterbath with hold-down rollers |

- Vacuum waterbath with Venturi system

- Receiving table for vacuum waterbath and measuring / testing equipment

- 1000mm motorized longitudinal adjustment of the receiving table

- Manual lateral and height adjustment

- Partial segment of the waterbath heatable

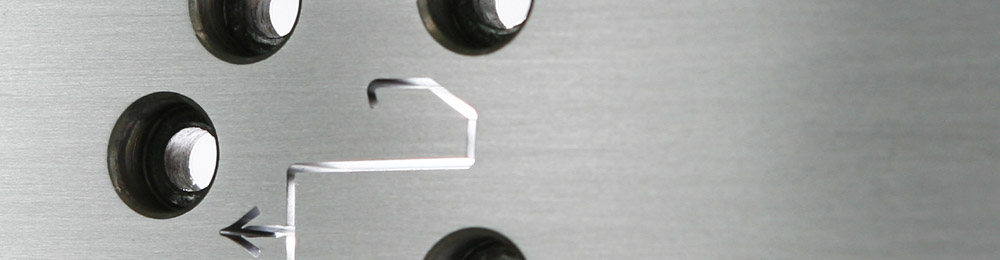

- Measuring chamber to accommodate an ultrasonic wall thickness measuring head