Project of the month October 2018:Complete line to produce droplet eliminator profiles made of PP TV 20

The task:

- Complete line with melt pump for two die systems

- Laser marking of the product inline

- Special saw for diagonal cuts

The solution:

- Extrusion line consisting of the following components:

- ME 75/5x30D with mini ME Control/4, screw with barrier part designed to process 300 kg/h

- Melt pump with manual screen changer

- Tooling system consisting of extrusion die, dry/wet calibration with waterbath, designed to run a production speed of 6m/min

- Calibration unit ME 14/6.2 with 3 frequency-controlled vacuum pumps

- Laser printing station

- Haul-off unit ME 30/6.3 with profiled, raised transport chain

- Cutting unit ME 50/6.2 designed for vertical diagonal cuts

|

|

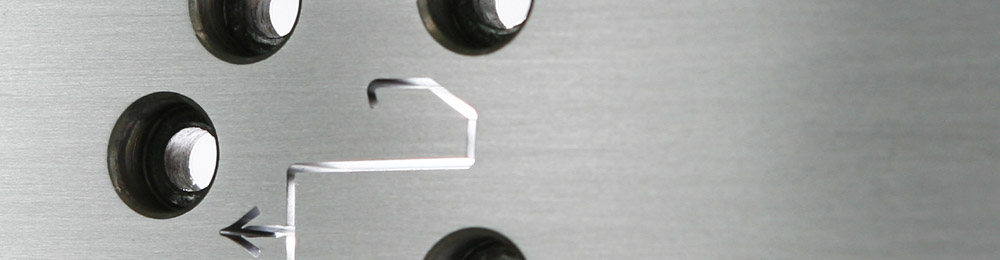

| Extrusion die with melt pump | Manual screen changer with melt pump |

|

|

| Calibration system | Waterbath |

|

|

| Laser printer Laserdrucker | Laser marking |

|

|

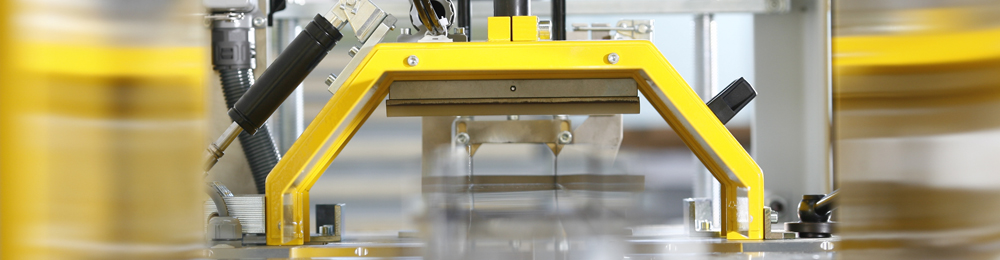

| Haul-off ME 30/6.3 | Profiled, high-raised transport transport chain |

|

|

| Cutting unit ME 50/6.2 | Controller ME Control 20/4 |